Revolutionizing Chemical Processing: The Advantages of Structured Packings

September 3, 2024

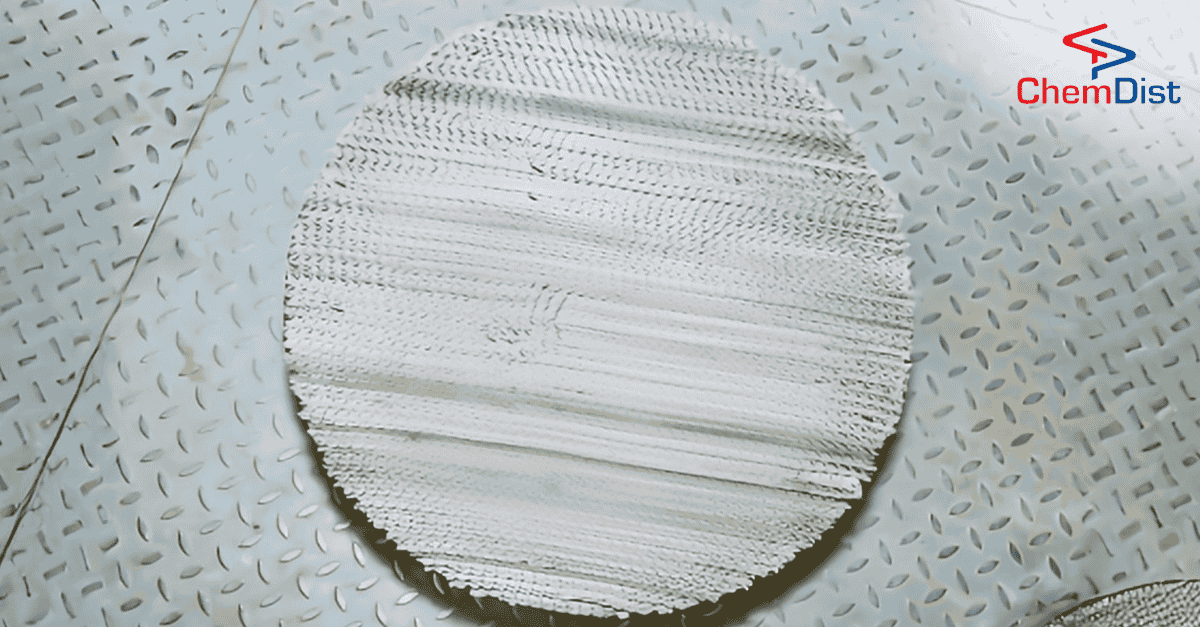

Structured packings is a key technology in chemical processing, especially in distillation and separation processes. Its primary function is to increase the surface area within a distillation column, enabling efficient vapor-liquid contact, which is crucial for effective separation. The structured packings process involves stacking carefully designed materials, such as metal or plastic, in a specific arrangement that maximizes the contact area between the gas and liquid phases.

One of the primary benefits of structured packings is its efficiency. Compared to traditional tray-based systems, structured packings can improve separation efficiency by up to 50% or more. This improvement leads to significant cost savings, as it reduces the energy required for separation, leading to lower operational costs. Additionally, structured packings reduce the pressure drop across the column, which further enhances energy efficiency and reduces wear and tear on equipment.

The manufacturing process of structured packings is a meticulous one, involving the precise cutting and shaping of materials to create a uniform structure. The materials used are typically corrosion-resistant, ensuring longevity and durability in harsh chemical environments. The design of structured packings also allows for easy scaling, making it suitable for a wide range of industrial applications, from small-scale laboratory setups to large-scale industrial plants.

In terms of statistics, the adoption of structured packings in distillation columns has grown rapidly over the past decade, with studies showing that it can reduce energy consumption by up to 30% compared to traditional methods. This has made it a preferred choice for industries looking to optimize their processes while reducing their environmental footprint.

In conclusion, structured packings are a game-changer in the chemical processing industry. Its ability to enhance efficiency, reduce costs, and improve sustainability makes it an indispensable tool for modern chemical plants. With continuous advancements in material science and design, structured packings will likely play an even more significant role in the future of chemical processing.